Our R&D center is committed to constantly researching and improving the application of microenvironment controls within showcases. This research focuses on increasing control over air exchange and the relative humidity in showcases, eliminating suspended particles and polluting gases, designing convenient and safe opening methods, filtering ultraviolet and infrared radiation, and creating customized environments within showcases, among other initiatives. All new mechanical devices and new materials are subject to strict testing and inspection by our R&D laboratory. With technical support from our R&D center.

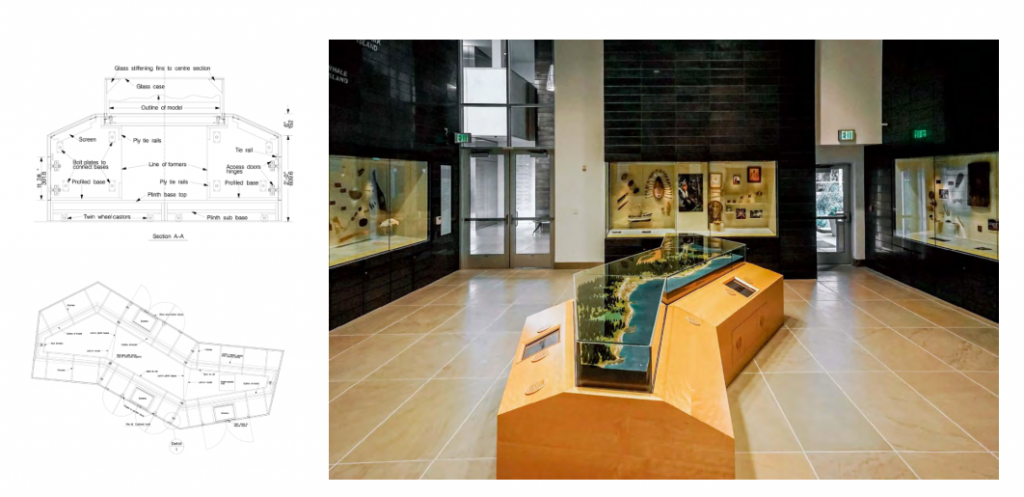

Display Pedestal

Pedestal of showcases and the exterior facings of these plinths are composed of different materials, most commonly steel plates, wood, and stone. You can make your decision on the type of material to choose based on the weight of the exhibits and the weight-bearing capacity of the plinth base. The standard design is a steel plinth base with a weight-bearing capacity of 150Kg/m2 and an electrostatic coated steel plate finish on the exterior facing.

SELECTION OF GLASS

For security and safety reasons, we recommend laminated glass. The PVB interlayer in laminated glass will hold the glass together if broken, protecting the exhibits inside. In addition, the PVB interlayer resists penetration or physical attack by forming a physical barrier against theft. Moreover, laminated glass can filter 99% of ultraviolet rays from the light outside showcases within a wave length of 280~380nm.

Available glass types include:

COMMON FLOAT GLASS

EXTRA-CLEAR GLASS

ANTI-REFLECTIVE GLASS

ACCESS OR OPENING OF SHOWCASES

The design of the opening method for showcases will depend on the type of showcase, its size and position, the size of the exhibit, the operating preferences of the museum staff and other factors. Regardless of the opening method, we take close safety precautions and ensure independent operation by one person.Beside horizontally hinged access,the choices available are

Pedestal of showcases and the exterior facings of these plinths are composed of different materials, most commonly steel plates, wood, and stone. You can make your decision on the type of material to choose based on the weight of the exhibits and the weight-bearing capacity of the plinth base. The standard design is a steel plinth base with a weight-bearing capacity of 150Kg/m2 and an electrostatic coated steel plate finish on the exterior facing.

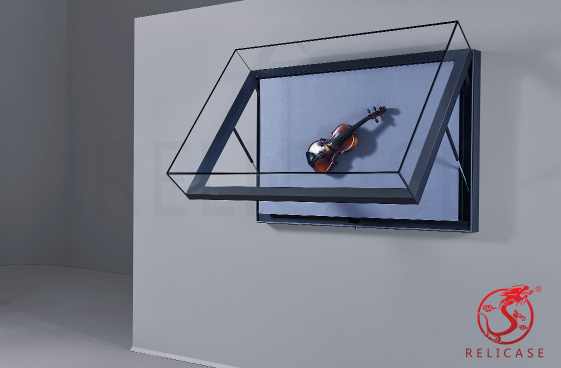

HINGED SIDE OPNING

100% opening access

DOUBLE-LEAF ACCESS

90% opening acces

PULL & SLIDE DOOR

90% opening access

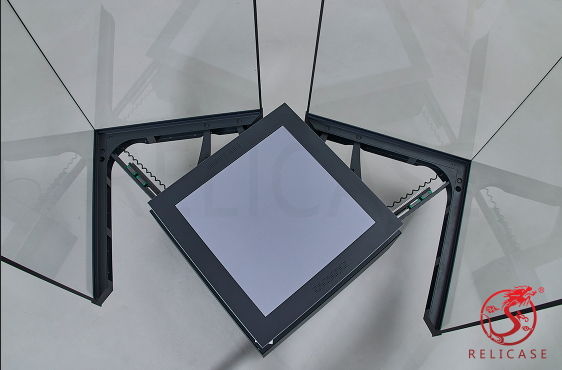

PIVOT & HINGED TOP ACCESS

The opening access is greater than the display height

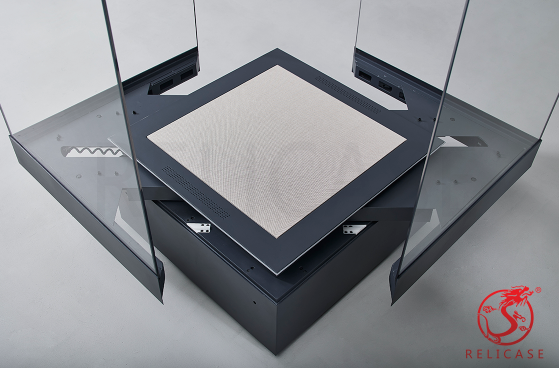

DRAWER ACCESS

100% opening access

DISPLAY ENVIRONMENTAL CONTROL

The interior of a showcase is a relatively air-tight environment. We create a stable inner environment within the showcase to ensure your exhibits do not suffer damage from changes in environmental factors outside the case.

The protection we provide is:

AUTOMATIC DISPLAY HANGING SYSTEM

TEMPERATURE CONTROL

OXYGEN CONTROL

HAZARDOUS SUBSTANCES CONTROL

LIGHTING

We provide a variety of lighting solutions to meet clients’ different needs.

- LOW VOLTAGE

- HALOGEN LIGHTS

- FIBRE OPTIC LIGHTING

- FLURESCENT LIGHT

- LED LIGHT

AUXILIARY FUNCTIONS

LIGHTING MODULES

AUTOMATIC DISPLAY HANGING SYSTEM

SHOWCASE COMPREHENSIVE MANAGEMENT SYSTEM (TCFA)

OUR SERVICE APPROACH

Through in-depth communication with our Clients, we achieve a thorough understanding of our clients’ overall design and planning objectives for the exhibition. This approach comprehensively outlines their needs and specifications.

By drawing on our in-depth experience of cultural relics and museum exhibitions, our designers, along with museum curators, conservators, historians, consultant architects and other experts will assist the Client in the development of their project ideas and manage the details to a successful project solution.

Our technically advanced factory and skilled professionals will ensure high quality products that perfectly match the design.

The ISO9001 quality control system is implemented throughout our production processes. This effectively guarantees the optimal production and fabrication of each and every component. Inspections are conducted to ensure the products meet the client’s specifications.

All items are carefully packed and protected against damage. Shipments are monitored throughout every stage of the cargo’s journey to the destination. Our logistics department provides continual updates on the progress of the shipment until it reaches its destination.

Our on-site installation team has the highest level of technical training and extensive installation experience. All components and individual product units come together at this final stage.

Our professional after-sales service ensures that each product is in perfect working condition. We are available at all times to provide technical consultation and updates on information